Professional, rigorous and honest. TOP, a reliable brand for you.

Abide by "customer first, integrity based, pursuit of perfection, team win-win" corporate values

Product

-

TVS-400

-

Powder conveyor sieving station

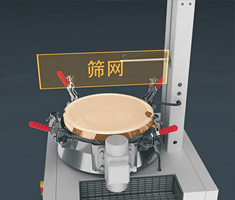

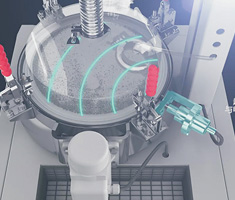

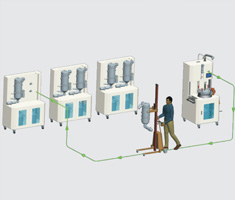

- TVS-400 series is a combination of powder conveyor andsieving station,mainly used in safe areas to recover and screen nonreactive powder in metal 3D printing industry,such as stainless steel,nickel alloy,marging steel etc.During the sieving job processing,the sieving inside environment have to be considered as a hazardous area Zone 20,thus explosion proof is necessary for this powder sieving machine.

-

| Product description |

|

TVS-400 series is a combination of powder conveyor andsieving station,mainly used in safe areas to recover and screen non-reactive powder in metal 3D printing industry,such as stainless steel,nickel alloy,marging steel etc.During the sieving job processing,the sieving inside environment have to be considered as a hazardous area Zone 20,thus explosion proof is necessary for this powder sieving machine. |

| Product Features | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Technical data | ||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||

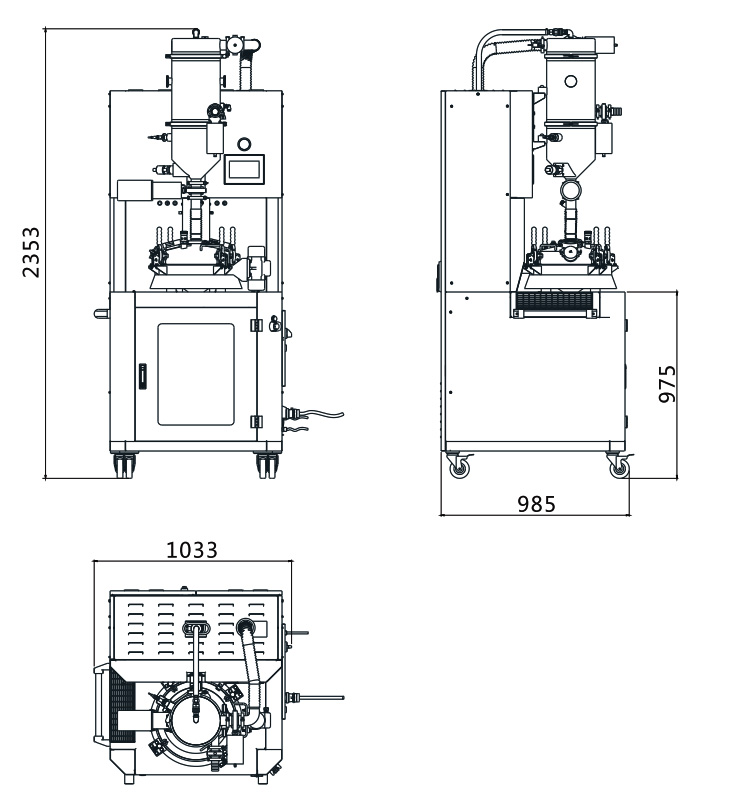

| Outline size |

| L*W*H(mm):985x1033x2353 |

|

Contact us

在线留言