Professional, rigorous and honest. TOP, a reliable brand for you.

Abide by "customer first, integrity based, pursuit of perfection, team win-win" corporate values

Product

-

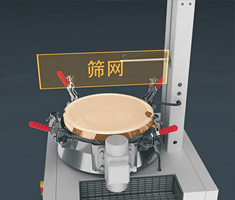

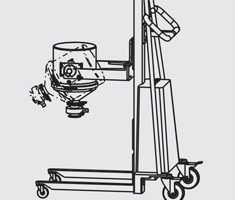

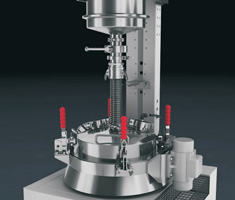

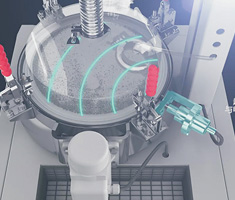

TSF-400

-

Sieving station

- This machine used for powder reclaim purpose. Lots of Titanium and Aluminium powder can be considered to be recycled for re-use after 3D printing finished. During the sieving job processing, inside environment have to be considered as a hazardous area zone 20, explosion proof is necessary.

-

Description

Description

Video

Related Suggestion

Certificates

Downloads

Description

| Product description |

|

This machine used for powder reclaim purpose. Lots of Titanium and Aluminium powder can be considered to be recycled for re-use after 3D printing finished. During the sieving job processing, inside environment have to be considered as a hazardous area zone 20, explosion proof is necessary. Ultrasonic is a good choice for this mesh clear system, and the efficiency will be ten times than motor only. The powder particles will be easily oxidized if touch with the air. Inert gas input system had been designed for protecting these powder during sieving job process to keep powder reach a good quality. Meanwhile inert gas will act a role of explosion proof function. |

| Product Features | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Description

| Technical data | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

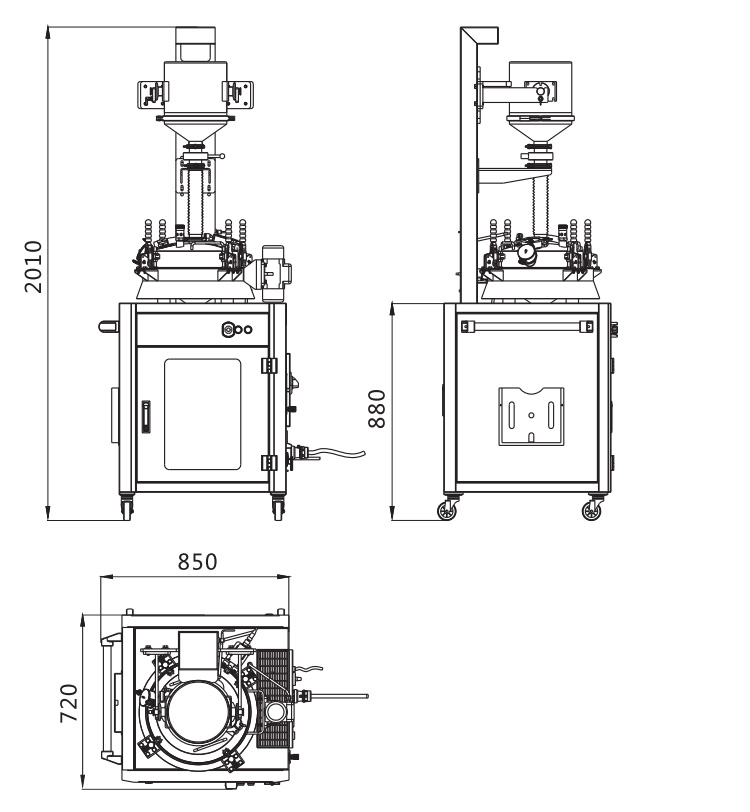

| Outline size |

| L*W*H(mm):720x850x2010 |

|

Video

Related Suggestion

Certificates

Downloads

Contact us

在线留言

Description:

在线留言