Professional, rigorous and honest. TOP, a reliable brand for you.

Abide by "customer first, integrity based, pursuit of perfection, team win-win" corporate values

Product

-

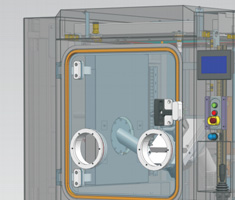

TCB-100 Powder cleaning station

-

AM parts powder removal system

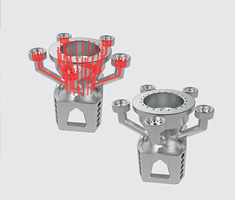

- This series of equipment is mainly used in safe area to clean the residual powder of 3D printing parts in a complex geometric path, which is difficult to clean by conventional technology. Metal powders are usually flammable and explosive, so explosion protection is a necessary performance of the equipment.This series of equipment has been certified by a third-party authorized body.

-

Description

Description

Video

Related Suggestion

Certificates

Downloads

Description

| product description |

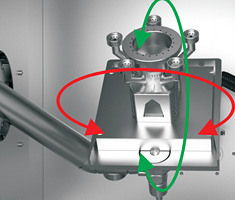

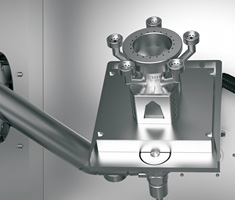

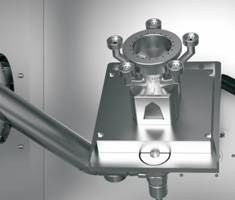

This series of equipment is mainly used in safe area to clean the residual powder of 3D printing parts in a complex geometric path, which is difficult to clean by conventional technology. Metal powders are usually flammable and explosive, so explosion protection is a necessary performance of the equipment.This series of equipment has been certified by a third-party authorized body. Inert gas protection type can be choice for different powder. Closed glove box design, machine can be operated with environmental friendly. Angle can be adjusted in 360° for easy cleaning its . powder inside. Parts angle can be controlled by both program and manual. Meanwhile a ergonomic design rocker for easy operation. Blowing and vacuum device are designed to match dust vacuum facility . TCB-100 with inert gas protection system, oxygen and pressure detection in real time. |

| product Features | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Description

| Technical data | ||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

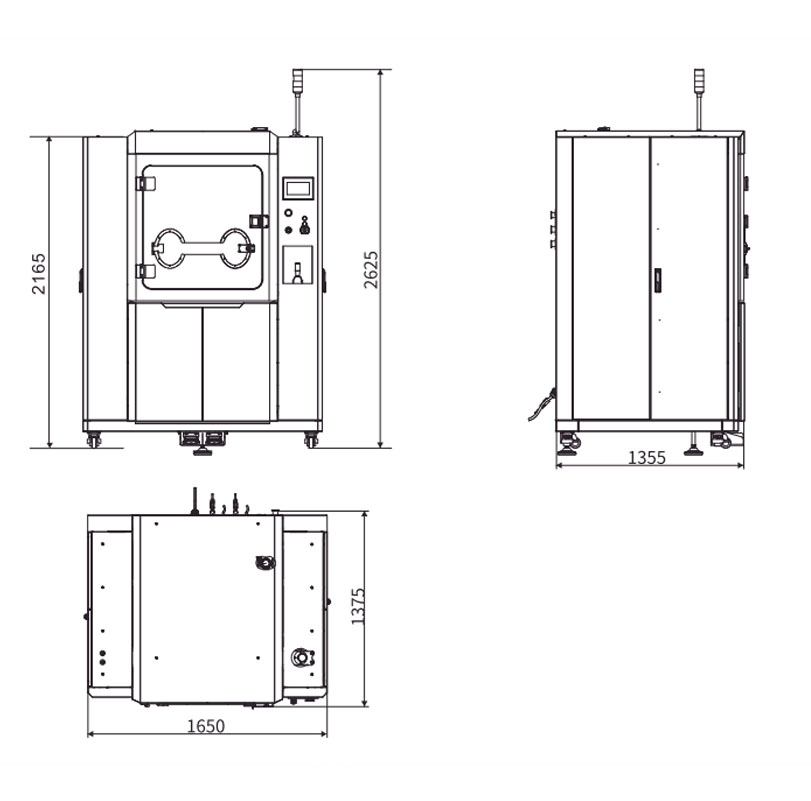

| Outline size |

| L*W*H(mm):1650x1355x2625 |

|

Video

Related Suggestion

Certificates

Downloads

Contact us

在线留言

Description:

在线留言