Products

TEX7-E 3KW IB 9L

Explosion proof-Three phase-Wet type

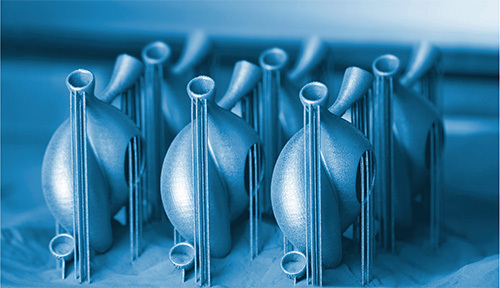

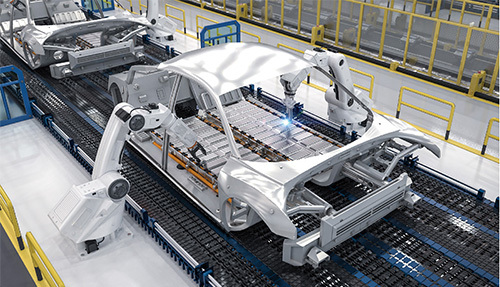

This series of products are electric explosion-proof vacuum cleaners, suitable for Zone 22 of explosive dust environments. They are used for cleaning and recovering high-risk dust such as aluminum powder and titanium powder. They are widely applied in industries such as aerospace, military, chemical pharmaceuticals, mechanical processing, and metal 3D printing.

- Description

- Specifications

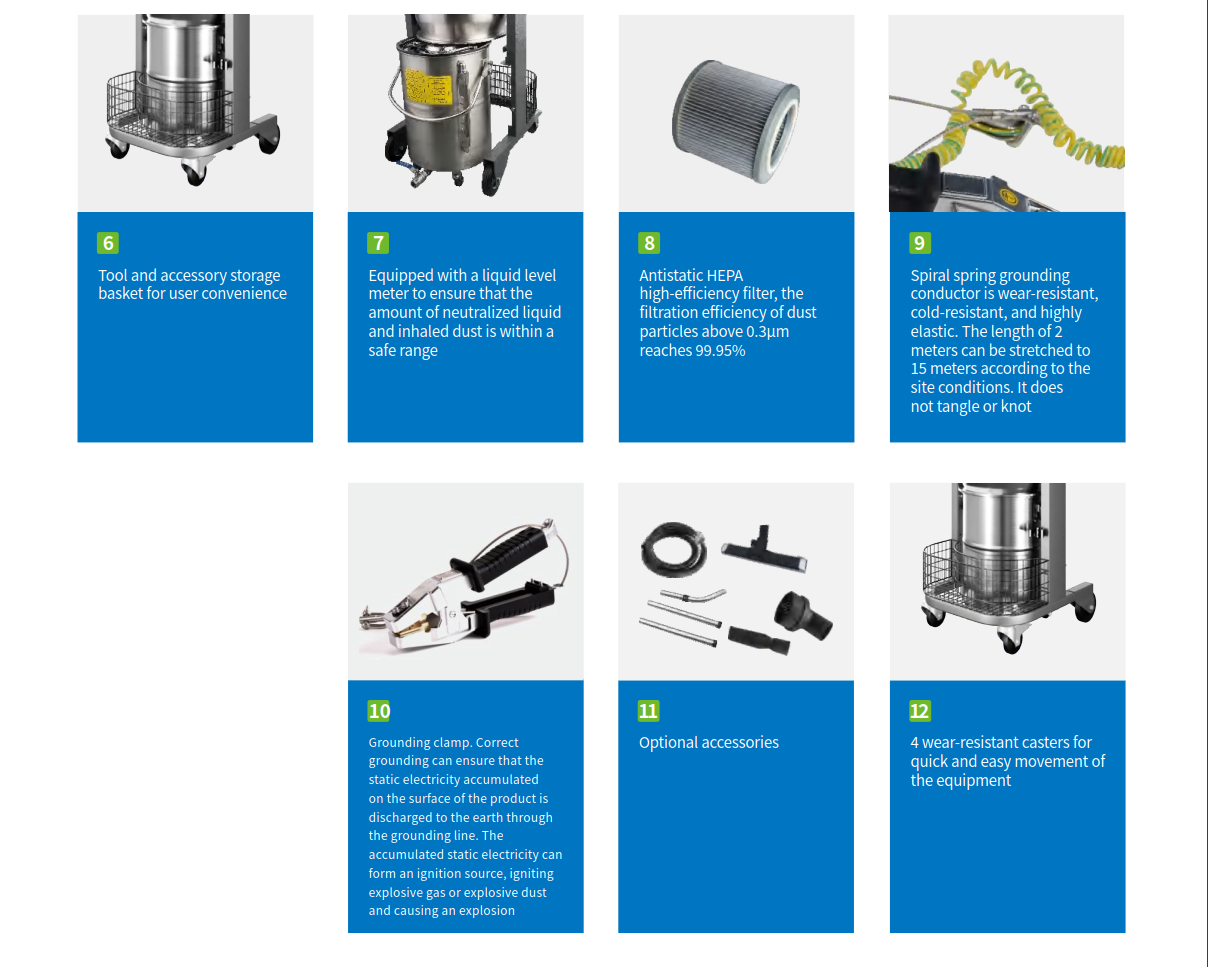

- Video

-

- Commodity name: Explosion proof-Three phase-Wet type

- Commodity ID: TEX7-E 3KW IB 9L

This series of products are electric explosion-proof vacuum cleaners, suitable for Zone 22 of explosive dust environments. They are used for cleaning and recovering high-risk dust such as aluminum powder and titanium powder. They are widely applied in industries such as aerospace, military, chemical pharmaceuticals, mechanical processing, and metal 3D printing.

INTRODUCTION This series of products are electric explosion-proof vacuum cleaners, suitable for Zone 22 of explosive dust environments. They are used for cleaning and recovering high-risk dust such as aluminum powder and titanium powder. They are widely applied in industries such as aerospace, military, chemical pharmaceuticals, mechanical processing, and metal 3D printing.

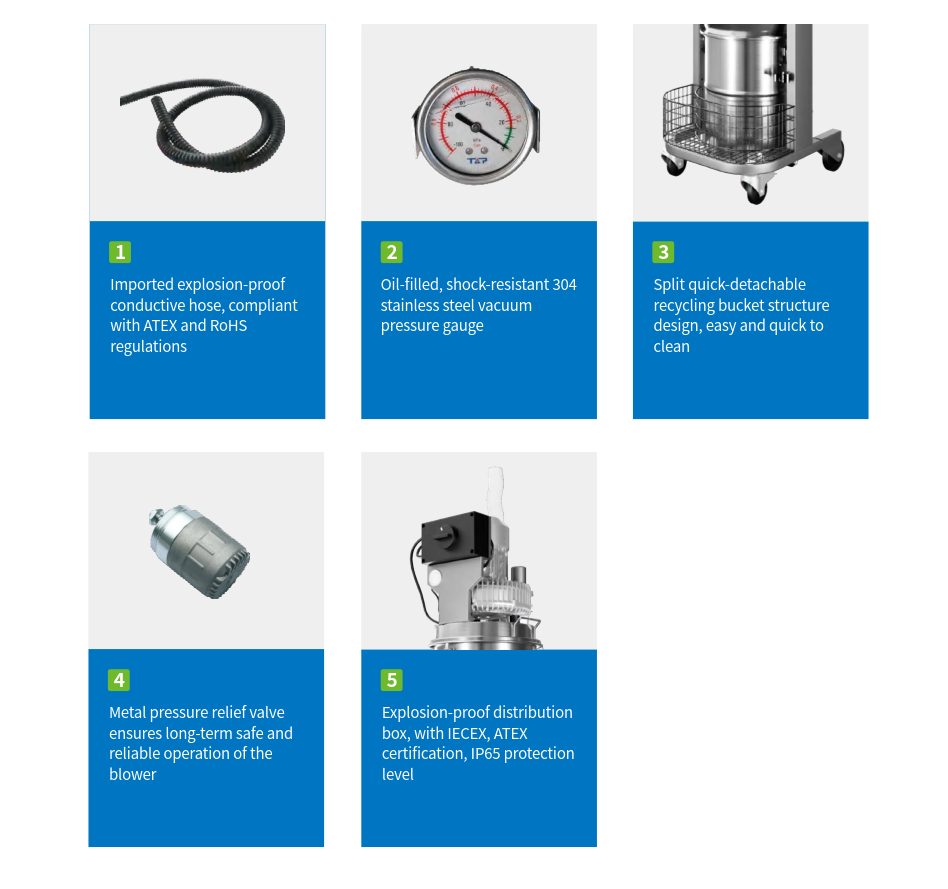

The overall structure of the wet (immersion bath) type explosion-proof vacuum cleaner is made of stainless steel. The frame is made of carbon steel coated with plastic. The entire machine has a solid and reliable structure.

The highly hazardous dust recovered by this series of explosion-proof vacuum cleaners is fully neutralized with the liquid in the container, thus preventing the dust from undergoing dangerous phenomena such as high temperature, combustion or explosion. The liquid used for neutralizing the dust should be selected based on the characteristics of the inhaled dust. Commonly used liquids include water, paraffin oil, mineral oil, etc. The principle for selecting the neutralizing liquid is to ensure that no chemical reaction occurs between the dust and the liquid, which could lead to the generation of flammable gases, high temperatures, or fires.Feature

-

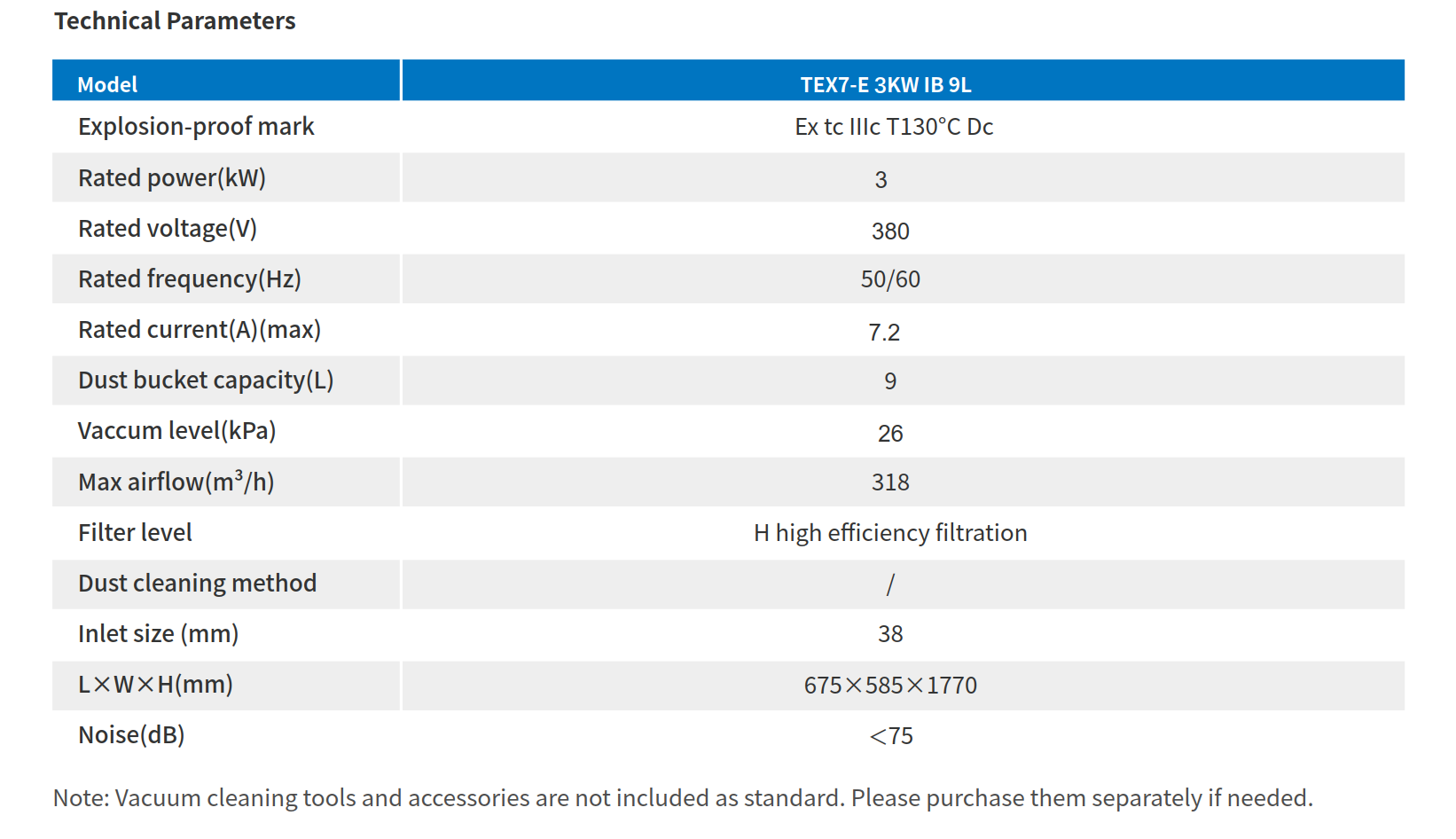

TECHNICAL DATA

Previous Page

Next Page

Previous Page

Next Page

For further information, please call the contact number400-811-8878Thank you for your support!

For further information, please call the contact number400-811-8878Thank you for your support!