Products

TCB-300

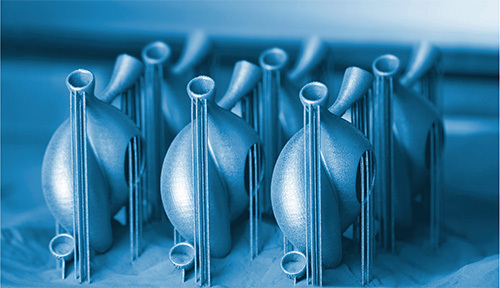

AM parts powder removal system

This equipment series primarily serves to establish a secure operational environment for technicians to remove residual metal powder from metal AM parts, particularly targeting powder trapped within intricate internal geometric structures, narrow crevices, and heavy-weight workpieces where conventional manual cleaning operations present significant safety challenges. Given the inherent combustible and explosive properties of metal powders commonly employed in 3D printing processes (e.g., aluminum and titanium powders), integrated explosion-proof design constitutes an essential performance requirement. The equipment series has undergone rigorous certification by accredited third-party authoritative institutions, with confirmed compliance with regulatory standards governing explosion prevention.

- 产品描述

- 规格

- 视频

- 附件

- 认证

- 下载

-

- Commodity name: AM parts powder removal system

- Commodity ID: TCB-300

This equipment series primarily serves to establish a secure operational environment for technicians to remove residual metal powder from metal AM parts, particularly targeting powder trapped within intricate internal geometric structures, narrow crevices, and heavy-weight workpieces where conventional manual cleaning operations present significant safety challenges. Given the inherent combustible and explosive properties of metal powders commonly employed in 3D printing processes (e.g., aluminum and titanium powders), integrated explosion-proof design constitutes an essential performance requirement. The equipment series has undergone rigorous certification by accredited third-party authoritative institutions, with confirmed compliance with regulatory standards governing explosion prevention.

Product Description This series of equipment integrates fully automatic inert gas protection functionality, enabling customizable atmosphere configuration within the powder cleaning chamber while providing real-time online monitoring of critical atmosphere parameters including oxygen content and pressure through integrated sensors. The system employs inflatable-sealed high-protection glovechamber doors to ensure hermetic containment during the cleaning process, effectively eliminating contamination risks and safeguarding operators' occupational health and safety.

The equipment utilizes servo motors to achieve 360-degree omnidirectional rotation of workpieces, ensuring thorough removal of residual powder from intricate internal channels regardless of complexity. Workpiece manipulation can be programmatically controlled via a touchscreen HMI (Human-Machine Interface) or manually operated through an ergonomic joystick, with adjustable rotation speed capability through joystick control.

The rotation platform incorporates two independently controlled vibration modes (high-frequency and low-frequency) that apply targeted vibrations to disintegrate compacted powder clusters within components, enhancing powder fluidity and detachment. Complementing this process, a high-pressure air gun kit facilitates efficient powder removal from confined spaces. Dislodged powder falls through to a dedicated suction port at the chamber base for connection to external recovery systems, while an integrated manually sealed suction hose allows direct extraction of residual powder from AM parts surfaces.

Product Features

-

Specifications

Previous Page

For further information, please call the contact number400-811-8878Thank you for your support!

For further information, please call the contact number400-811-8878Thank you for your support!