Products

TFU

Filter unit

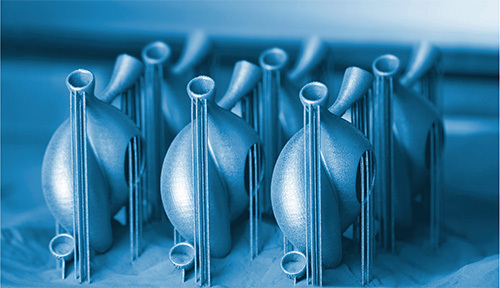

The TFU filter unit adopts a fully enclosed bag-in-bag-out design. During the use and maintenance of the equipment, it is carried out under the protection of bag replacement. The filter element and the interior of the cavity do not come into direct contact with people and the outside air, thus effectively preventing the contamination of highly active, highly toxic and highly allergenic materials. This design can effectively avoid occupational exposure risks and ensure the safety of personnel and the environment.

- Description

- Specifications

- Video

-

- Commodity name: Filter unit

- Commodity ID: TFU

The TFU filter unit adopts a fully enclosed bag-in-bag-out design. During the use and maintenance of the equipment, it is carried out under the protection of bag replacement. The filter element and the interior of the cavity do not come into direct contact with people and the outside air, thus effectively preventing the contamination of highly active, highly toxic and highly allergenic materials. This design can effectively avoid occupational exposure risks and ensure the safety of personnel and the environment.

INTRODUCTION Full-Range Safety Protection: Dual Safeguarding for Personnel and Environment

The TFU filtration unit adopts a fully enclosed bag-in/bag-out (BIBO) design. During operation and maintenance, all procedures are conducted under the protection of replacement bags. The filter cartridges and chamber interior do not directly contact personnel or external air, effectively preventing contamination from highly active, toxic, or allergenic materials. This design eliminates occupational exposure risks, ensuring safety for both personnel and the environment.FEATURE 1. Multi-Scenario Flexibility

The compact device allows flexible layouts to optimize space utilization. It operates in both horizontal and vertical airflow environments, can be independently installed in ducts, or assembled in multi-row/modular stacking configurations based on airflow requirements.2. Configurable Safety Features for Enhanced Adaptability

The system supports customizable combinations of pre-filtration, primary filtration, and tertiary filtration stages. Each stage can optionally integrate medium-efficiency, sub-HEPA, HEPA, ULPA, or activated carbon filters to meet diverse application needs.3. High-Efficiency DOP Testing Port: Ensuring Compliance with Environmental Standards

In modern industry, ensuring air emissions meet environmental standards is a critical corporate and regulatory obligation. Defects in HEPA filters or their installation (e.g., filter micro-leaks or sealing gaps) may compromise purification efficiency. Thus, post-installation or replacement, leak testing via the DOP method (using DOP solvent as a particle source with aerosol photometer detection) is essential to validate compliance. This ensures air quality and strengthens environmental stewardship.4. High Sealing Integrity for Stable Operation

Advanced structural design and precision welding ensure exceptional airtightness (±15000Pa pressure resistance) and mechanical robustness. This minimizes operational disruptions, reduces maintenance frequency, and extends equipment lifespan.5. Integrated Differential Pressure Monitoring for Efficient Maintenance

A differential pressure gauge enables real-time monitoring of filter status, allowing precise determination of replacement intervals. (Optional pressure signal output for centralized control systems.) Maintenance personnel can perform BIBO cartridge replacements via access doors, ensuring safe and efficient operations.

Previous Page

Next Page

Previous Page

Next Page

For further information, please call the contact number400-811-8878Thank you for your support!

For further information, please call the contact number400-811-8878Thank you for your support!