Products

TBD100

Inert powder mixer

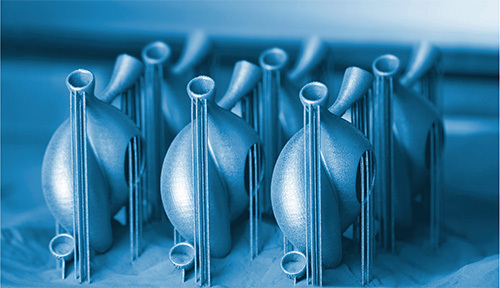

Inert gas powder mixer is widely used in 3D printing, pharmaceutical, food, coating, building materials, chemical industry and other industries, the equipment can be according to the user's product process for single powder, granular material or a variety of powder mixing, to meet different product process and production needs. Powder material is uniform distribution, the better performance of product quality, the mixer adopts hopper to turn 360 °, and 30 ° to the driven rotary axis, powder will be 360° free fall and roll, at the same time do high speed tangential motion along the hopper bucket wall, With the square cone hopper and 30° Angle design can make the material in the rolling and tangential movement, impact, bumping, diversion more intense,, reach the best mixing effect. In order to better ensure the powder, granular material physical properties and chemical properties do not change in the process of mixing, the device is equipped with inert gas protection function, input the inert gas mixing hopper, and oxygen content of sensors to monitor the oxygen value inside the hopper, ensure material in the process of mixing environment remain the inert gas in the hopper, the material will not be oxidation or other microscopic chemical reaction.

- Description

- Specifications

- Video

-

- Commodity name: Inert powder mixer

- Commodity ID: TBD100

Inert gas powder mixer is widely used in 3D printing, pharmaceutical, food, coating, building materials, chemical industry and other industries, the equipment can be according to the user's product process for single powder, granular material or a variety of powder mixing, to meet different product process and production needs. Powder material is uniform distribution, the better performance of product quality, the mixer adopts hopper to turn 360 °, and 30 ° to the driven rotary axis, powder will be 360° free fall and roll, at the same time do high speed tangential motion along the hopper bucket wall, With the square cone hopper and 30° Angle design can make the material in the rolling and tangential movement, impact, bumping, diversion more intense,, reach the best mixing effect. In order to better ensure the powder, granular material physical properties and chemical properties do not change in the process of mixing, the device is equipped with inert gas protection function, input the inert gas mixing hopper, and oxygen content of sensors to monitor the oxygen value inside the hopper, ensure material in the process of mixing environment remain the inert gas in the hopper, the material will not be oxidation or other microscopic chemical reaction.

Product description Inert gas powder mixer is widely used in 3D printing, pharmaceutical, food, coating, building materials, chemical industry and other industries, the equipment can be according to the user's product process for single powder, granular material or a variety of powder mixing, to meet different product process and production needs.

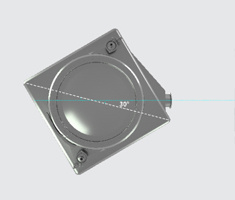

Powder material is uniform distribution, the better performance of product quality, the mixer adopts hopper to turn 360 °, and 30 ° to the driven rotary axis, powder will be 360° free fall and roll, at the same time do high speed tangential motion along the hopper bucket wall, With the square cone hopper and 30° Angle design can make the material in the rolling and tangential movement, impact, bumping, diversion more intense,, reach the best mixing effect.

In order to better ensure the powder, granular material physical properties and chemical properties do not change in the process of mixing, the device is equipped with inert gas protection function, input the inert gas mixing hopper, and oxygen content of sensors to monitor the oxygen value inside the hopper, ensure material in the process of mixing environment remain the inert gas in the hopper, the material will not be oxidation or other microscopic chemical reaction.

This product adopts the modular design, the mixing hopper and the host adopts use fast connection, the replacement is simple and fast, can be downward compatible with a number of different specifications of the mixing hopper, can achieve one machine multiple hoppers configuration, to meet the small batch, multi-variety mixing requirements.

Note: the picture in the file is slightly different from the actual product, please take the real product as the standard.

Product Features  1

1Electrical components are used international brands, such as ABB, Siemens, Phoenix and Schneider etc. The control system operation interface is simple and ergonomic.  2

2Mixing hopper adopts modular design, a host machine can be configured with a variety of volume hopper, can meet the mixing of different materials.

3

3The hopper adopts the square cone structure and the rotation spindle is arranged at an Angle of 30°, which can make the material have stronger jolt, impact and roll action and mix more evenly.

4

4The hopper outlet is equipped with butterfly valve, easy to clean, opening device is designed with anti-misoperation mechanism, safe and reliable work, the butterfly valve sealing ring material is sanitary silicone rubber, meet to GMP  5

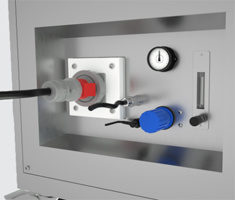

5With inert gas protection and oxygen content monitoring function, can effectively prevent the risk of material oxidation and dust explosion.

6

6The rotary spindle is directly driven by helical and cone tooth reducer frequency conversion brake motor, which drives the mixed hopper to rotate. It has high transmission efficiency, compact structure, adjustable speed and braking, meet the requirements of different rotating speeds and accurate positioning.  7

7Safety guardrail is provided around the mixing hopper. When the guardrail is lifted, the equipment will stop automatically. Only when the guardrail status is protected, the equipment is allowed to be started, which can effectively prevent the occurrence of dangers.  8

8Equipped with special grounding socket and cable, effectively prevent electrostatic accumulation, electric leakage and shock risk.

9

9Adopts the skeleton structure design, adopts welding procedure, high strength and good property.  10

10Equipped with printer, can carry out historical data consulting, printing, production process traceability and ledger management.

11

11Mixed-hopper, protective guardrail, electric control box, body exposed structure are made of SUS304 stainless steel material, corrosion resistance, wear resistance, high strength, easy to clean and elegant.  12

12Equip with Siemens touch screen, ABB emergency stop button and buzzer, the touch screen can be used for equipment operation, parameter setting and fault information check, the buzzer for action reminder, the emergency stop button for quick shutdown if any emergency. -

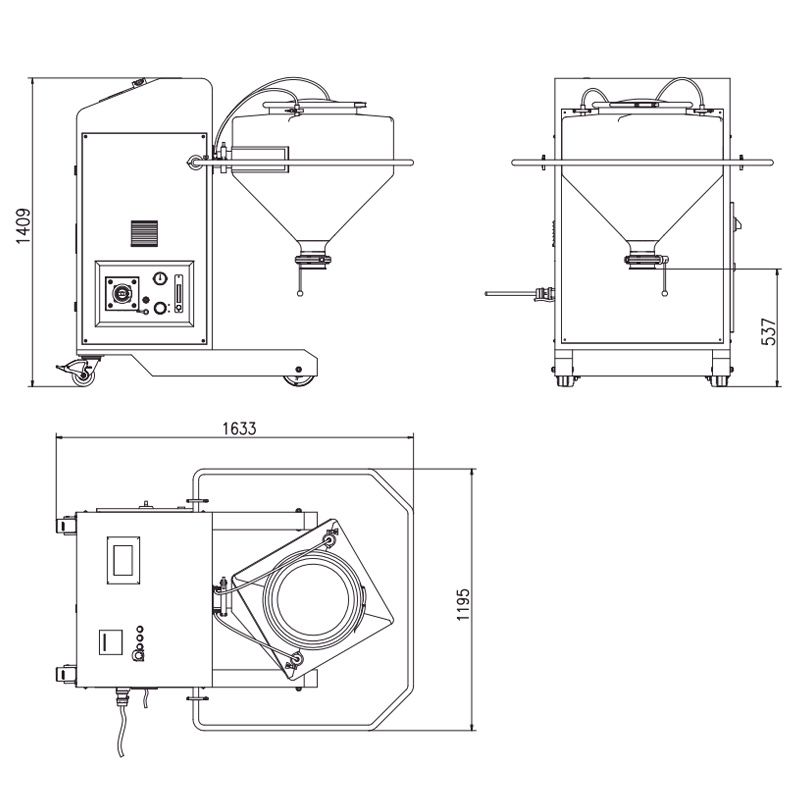

Technical data Order No. TBD100Rated voltage (V)

380,3P/N/PERated frequency (Hz)

50Rated current(A)1.5Rated power(kW0.8Capacity(L)100Rated weight(kg)100Speed(rpm)3 ~ 15Inert pressure(bar)4 ~ 6Inert flow (L/min)60 sound level(dB)<70 outlet sizeKF50Outline size L*W*H(mm):1633x1195x1409

-

For further information, please contact info@iectop.com, thank you for your support!

For further information, please contact info@iectop.com, thank you for your support!

Previous Page

Next Page

Previous Page

Next Page

For further information, please call the contact number400-811-8878Thank you for your support!

For further information, please call the contact number400-811-8878Thank you for your support!