Products

TGB800

Inert powder packing machine

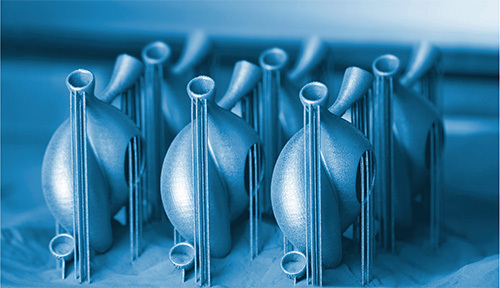

Inert powder packing machine is widely used in 3D printing, pharmaceutical, chemical and other industries, the equipment with inert protection circulation, clean O₂ steam, and other organic gases, for packing powder and granule materials prevent from oxidation or chemical reactions , extend the storage time of powder. For example 3D printing industry adopted by the metal aluminium powder, titanium powder, etc., if directly exposed to the air for filling and sealing, aluminium powder or titanium powder between the gap will be filled with air, will be oxidation after a period of time, as well as adsorption of water vapor in the air, make powder binder into pieces or group, will affect the quality of 3D printing finished workpiece. The equipment with inert protection function, can monitor the packing chamber pressure and oxygen content in real time, to ensure that the powder and granule material are packaging in inert environment, materials will not be oxidation, can be stored for a long time without changing its physical and chemical properties.

- Description

- Specifications

- Video

-

- Commodity name: Inert powder packing machine

- Commodity ID: TGB800

Inert powder packing machine is widely used in 3D printing, pharmaceutical, chemical and other industries, the equipment with inert protection circulation, clean O₂ steam, and other organic gases, for packing powder and granule materials prevent from oxidation or chemical reactions , extend the storage time of powder. For example 3D printing industry adopted by the metal aluminium powder, titanium powder, etc., if directly exposed to the air for filling and sealing, aluminium powder or titanium powder between the gap will be filled with air, will be oxidation after a period of time, as well as adsorption of water vapor in the air, make powder binder into pieces or group, will affect the quality of 3D printing finished workpiece. The equipment with inert protection function, can monitor the packing chamber pressure and oxygen content in real time, to ensure that the powder and granule material are packaging in inert environment, materials will not be oxidation, can be stored for a long time without changing its physical and chemical properties.

Product description Inert powder packing machine is widely used in 3D printing, pharmaceutical, chemical and other industries, the equipment with inert protection circulation, clean O₂ steam, and other organic gases, for packing powder and granule materials prevent from oxidation or chemical reactions , extend the storage time of powder. For example 3D printing industry adopted by the metal aluminium powder, titanium powder, etc., if directly exposed to the air for filling and sealing, aluminium powder or titanium powder between the gap will be filled with air, will be oxidation after a period of time, as well as adsorption of water vapor in the air, make powder binder into pieces or group, will affect the quality of 3D printing finished workpiece.

The equipment with inert protection function, can monitor the packing chamber pressure and oxygen content in real time, to ensure that the powder and granule material are packaging in inert environment, materials will not be oxidation, can be stored for a long time without changing its physical and chemical properties.

Product Features  1

1Electrical components are used international brands, such as ABB, Siemens, Phoenix and Schneider etc. The control system operation interface is simple and ergonomic.  2

2The body is made of SUS304 stainless steel, and the outer surface is reinforced by square tube grid structure, which has high structural strength and strong pressure resistance.  3

3Germany imported double - stage oil seal vane vacuum pump, high vacuum degree, high efficiency, low sound level.

4

4Electrical components are used international brands, such as Festo and SMC. Performance is stable and reliable, quality is guaranteed.

5

5Equipped with special grounding, effectively prevent electrostatic accumulation and leakage, electric shock risk.

6

6Anodized aluminum alloy glove mouth, corrosion resistance, wear resistance, gloves equipped with internal and external pressure balance air path, prevent the gloves expansion or burst.

7

7Imported, anti-oxidation, wear-resistant high performance butyl synthetic rubber gloves, long service life.  8

8Tilt, removable, thickened, transparent acrylic glass window, better vision with clear window.  9

9The inert environmental replace oxygen efficiently.  10

10Monitor oxygen content and pressure in real time.  11

11Audible and visual alarm with text reminder, easier to use and safer. -

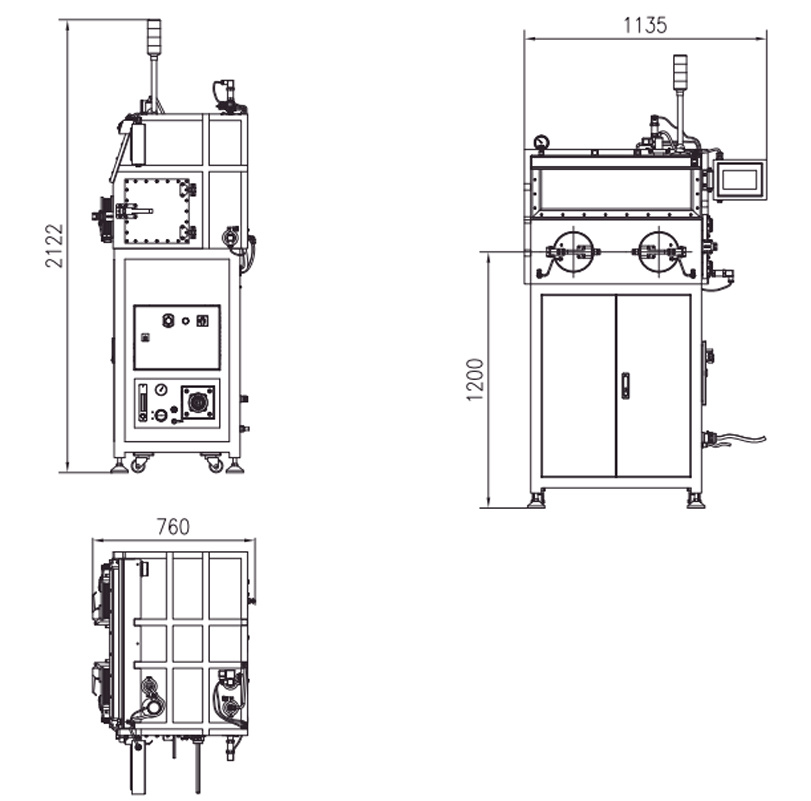

Technical data Order No. TGB800Ambient temperature (℃)

10~40Rated voltage ( V )

220,1P/N/PERated frequency(Hz)50Rated power (kW)

0.75Rated current(A)4.5Inner size L×W×H(mm)794×594×594Entry size W×H(mm)250×300Max working pressure Pa)-98000~+20000Rated flow(bar)4~6Inert pressure (%)0~25外形尺寸 L*W*H(mm):1135×760×2122

-

For further information, please contact info@iectop.com, thank you for your support!

For further information, please contact info@iectop.com, thank you for your support!

Previous Page

Next Page

Previous Page

Next Page

For further information, please call the contact number400-811-8878Thank you for your support!

For further information, please call the contact number400-811-8878Thank you for your support!