Products

TDM series

Grinding and Welding Dust Collect Workbench

Grinding and welding dust collector workbench is integrated grinding table and dust collector as one of the equipment.It is most suitable for small workpiece welding, grinding and other smoke - producing processing technology. It can design and manufacture and configure other accessories according to the actual work needs of customers.Such as vise, lighting, pneumatic tools air source interface, power interface, etc.To achieve a convenient operation platform with multiple functions in one. The grinding and welding dust collector workbench is also easy to move.It has filter material self-cleaning function.

- Description

- Specifications

- Video

-

- Commodity name: Grinding and Welding Dust Collect Workbench

- Commodity ID: TDM series

Grinding and welding dust collector workbench is integrated grinding table and dust collector as one of the equipment.It is most suitable for small workpiece welding, grinding and other smoke - producing processing technology. It can design and manufacture and configure other accessories according to the actual work needs of customers.Such as vise, lighting, pneumatic tools air source interface, power interface, etc.To achieve a convenient operation platform with multiple functions in one. The grinding and welding dust collector workbench is also easy to move.It has filter material self-cleaning function.

INTRODUCTION Grinding and welding dust collector workbench is integrated grinding table and dust collector as one of the equipment.It is most suitable for small workpiece welding, grinding and other smoke - producing processing technology.

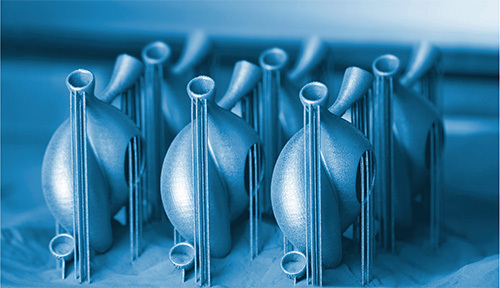

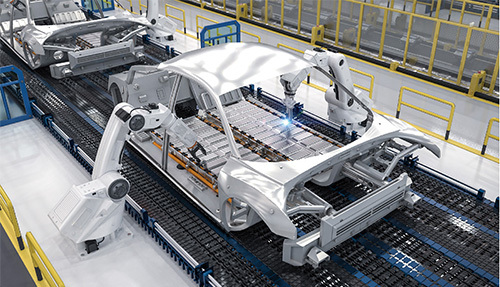

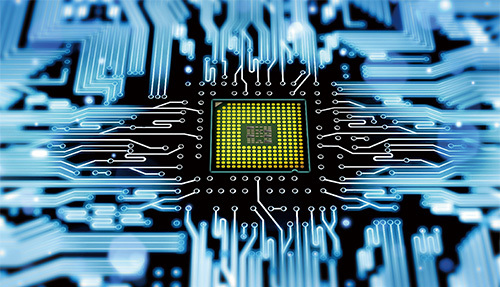

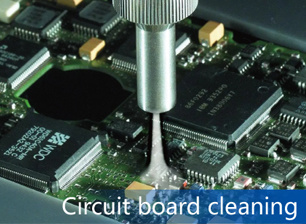

It can design and manufacture and configure other accessories according to the actual work needs of customers.Such as vise, lighting, pneumatic tools air source interface, power interface, etc.To achieve a convenient operation platform with multiple functions in one.The grinding and welding dust collector workbench is also easy to move.It can be moved to a new position at any time according to the change of plant layout and process requirements, connecting the air source and power supply can continue to use.Dust produced by pneumatic or electric grinding workpiece, including electric welding, gas welding dust. Under the power of the blower at the bottom of the table, it is inhaled under the table or on the side. Through sedimentation, diffusion and screening, the dust is intercepted by the filter material. The clean gas penetrates through the filter material and is discharged directly in the workshop by the fan without the need of the chimney.It has filter material self-cleaning function.With the increase of the dust thickness on the surface of the filter material, the pressure difference on the surface of the filter material increases. When the set parameter is reached, the pulse controller will automatically open and close the valve and start the compressed air blowing and cleaning the dust.APPLICABLE FIELDS AEROSPACEMACHINERYINDUSTRYELECTRONICSNEW MATERIALPRECISION

MANUFACTURINGWORKING PRINCIPLE ■ An underdraft platform with perforated plates can quickly collect soot into the chamber below the platform.Then through the built-in cartridge filtration, through the bottom of the integrated fan directly after the clean air discharged into the room.

APPLICATION PROCESS

-

TECHNICAL DATA TYPE TDM2000 TDM3000 TDM4000 Protection degreeIP54 Related power(kW)1.2 1.8 2.4 Related voltage(V)220-240 Related frequency(Hz)50/60 Table width(mm)800 1200 1500 Max airflow(m³)2000 3000 4000 Cartridge quantity1 2 4 Filtration area(m²)20 40 80 Blower static pressure(Pa)2800 2800 3800 Dust cleaningCompressed air automatic cleaningSound level(dB)≤65 ≤65 ≤70 L(mm)×W(mm)×H(mm)800×1000×1700 1200×1000×1700 1500×1000×1700

-

Previous Page

Next Page

Previous Page

Next Page

For further information, please call the contact number400-811-8878Thank you for your support!

For further information, please call the contact number400-811-8878Thank you for your support!