Products

TDC4/6-EX SERIES

EXPLOSION PROOF DUST COLLECTOR

TDC series cartridge dust collector is specially designed for multiples of explosive dust hazardous areas, can be used for variety of explosive dust collection and filtration.

- Description

- Specifications

- Video

-

- Commodity name: EXPLOSION PROOF DUST COLLECTOR

- Commodity ID: TDC4/6-EX SERIES

TDC series cartridge dust collector is specially designed for multiples of explosive dust hazardous areas, can be used for variety of explosive dust collection and filtration.

INTRODUCTION ■ Integrated StructureThe bottom-mounted explosion-proof fan module features an integrated design for quick and easy installation.

■ Anti-Static Filter Cartridges

The anti-static filter cartridges are combined with anti-static bonding across the entire unit and equipped with a full-system grounding device, ensuring reliable and safe anti-static grounding.

■ 65° Large-Inclination Design

The lower ash hopper of the dust collector adopts a 65° large-inclination design. An airlock discharge valve between the ash hopper and dust bin enables continuous ash removal, complying with national dust explosion prevention standards.

■ National Explosion-Proof CertificationThe equipment has obtained third-party whole-unit explosion-proof certification.

■ Integrated Multi-Functional Control System

The explosion-proof electrical control cabinet integrates a multi-functional control system, including fan control and protection, automatic pulse-jet cleaning, and the ability to switch between pressure differential or timed cleaning modes.

■ Internationally Renowned Explosion-Proof Devices

The dust collector is equipped with rupture discs or flameless venting devices tailored to its installation environment. The required venting area is calculated based on dust properties and operational conditions, with all rupture discs and flameless venting devices sourced from internationally renowned brands.

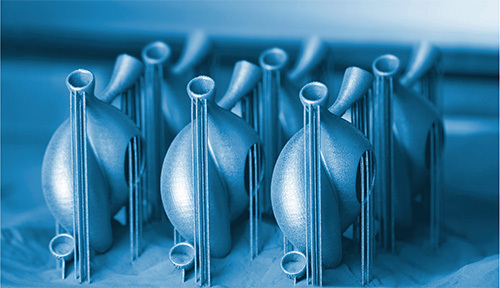

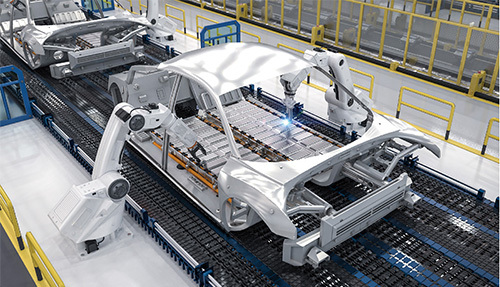

APPLICABLE FIELDS TRANSPORTATION AGRICULTURAL

SCI-TECHFOOD &

PHARMACEUTICALMACHINERY

INDUSTRYPRECISION

MANUFACTURINGWORKING PRINCIPLE ■ Dust and fumes are captured by the extractor arm or pipeline and enters the filter chamber under the power of the blower. When it passes through the horizontally placed cartridge, the particles are filtered and the clean air penetrates the filter material into the center of the cartridge, directly output indoor through the clean air chamber by blower.

■ With the accumulation of dust on the surface, the pressure difference will be gradually increased, which is directly shown in the magnehelic gauge. According to the instructions of magnehelic gauge, manual button pulse cleaning can be carried out to make the

dust on the surface of the cartridge fall off to the dust bin.APPLICATION PROCESS

-

TECHNICAL DATA TYPE TDC4-LEX TDC4-HEX TDC6-LEX TDC6-HEX Rated voltage380V,3P/N/PE Rated frequency50Hz Motor power(kW)4 5.5 5.5 7.5 Max airflow(m³/h)4000 5000 5000 7000 Capacity(L)60 60 60 60 Cartridge quantity(psc)4 4 6 6 Filter typeAnti-static materialFiltration area(m²)80 80 120 120 Filter degreeH Dust cleaningPulse cleaningCompressed air requirement5-6 bar clean and dry compressed air -

Previous Page

Next Page

Previous Page

Next Page

For further information, please call the contact number400-811-8878Thank you for your support!

For further information, please call the contact number400-811-8878Thank you for your support!