Products

TDD-EX Series

Cartridge Dust Collector

For explosion-proof dust, it can be used in dust explosion-proof zones 21 and 22. It is strictly designed and manufactured in accordance with the dust removal safety regulations for dust explosion sites such as GB15577-2018 and AQ4273-2016.

- Description

- Specifications

- Video

-

- Commodity name: Cartridge Dust Collector

- Commodity ID: TDD-EX Series

For explosion-proof dust, it can be used in dust explosion-proof zones 21 and 22. It is strictly designed and manufactured in accordance with the dust removal safety regulations for dust explosion sites such as GB15577-2018 and AQ4273-2016.

INTRODUCTION ■ Whole-Unit Anti-Static Grounding

From anti-static filter cartridges, cartridge brackets, and enclosure structure to motors and discharge valves, all conductive components are connected with equipotential bonding. An external grounding terminal is reserved on the device. After proper on-site grounding, the grounding resistance of any part of the equipment is ensured to be below 10Ω.

■ Evidence-Based Explosion Venting Measures

Whether configured with metal rupture discs or flameless venting devices, each design is based on venting area calculations specific to the application’s dust type and concentration data, ensuring compliance with explosion venting requirements.

■ Compliance with National Explosion-Proof Standards

Adopts a large-inclination (>65°) ash hopper design to ensure all hopper surfaces maintain an angle >65° relative to horizontal, minimizing dust accumulation risks. The hopper base is equipped with an airlock discharge valve interlocked with the blower, ensuring continuous dust transfer to the collection bin during operation. Additionally, the airlock valve isolates the filtration chamber from the dust collection bin.

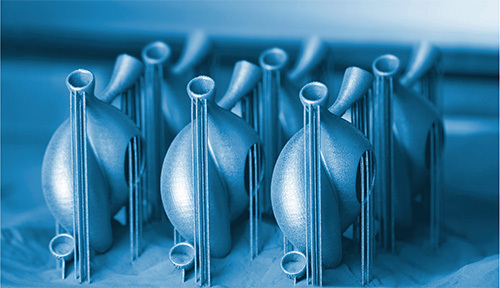

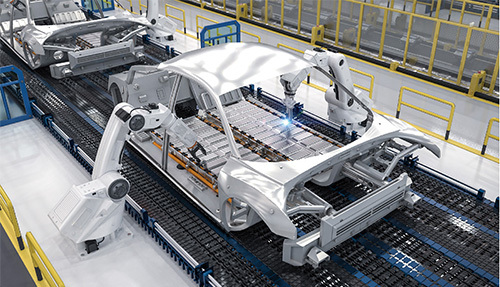

APPLICABLE FIELDS TRANSPORTATION AGRICULTURAL

SCI-TECHFOOD &

PHARMACEUTICALMACHINERY

INDUSTRYPRECISION

MANUFACTURINGAPPLICATION PROCESS

-

TECHNICAL DATA Specification Cartridge quantity(pc)

Filter area(㎡)

L×W×H(mm)

Weight(kg)

TDD2-4EX 4

80

1120×1700×2950

920

TDD3-6EX 6

120

1120×1700×3400

1000

TDD2-8EX 8

160

1200×2370×3550

1170

TDD2-12EX 12

240

1700×2370×3900

1330

TDD3-12EX 12

240

1200×2370×4050

1380

TDD4-16EX 16

320

1200×2370×4600

1600

TDD3-18EX 18

360

1700×2370×4350

1750

TDD3-24EX 24

480

2220×2370×4050

2400

TDD4-32EX 32

640

2220×2370×4600

2780

TDD3-36EX 36

720

3240×2370×4050

3440

TDD4-48EX 48

960

3240×2370×4600

4000

TDD3-54EX 54

1080

4780×2370×4350

3330

TDD3-60EX 60

1200

5260×2370×4050

4460

TDD4-64EX 64

1280

4240×2370×4600

6750

TDD3-72EX 72

1440

6280×2370×4050

6480

TDD4-80EX 80

1600

5260×2370×4600

9550

TDD4-96EX 96

1920

6280×2370×4600

12300

TDD4-112EX 112

2240

7300×2370×4600

15100

TDD4-128EX 128

2560

8320×2370×4600

17880

-

Previous Page

Next Page

Previous Page

Next Page

For further information, please call the contact number400-811-8878Thank you for your support!

For further information, please call the contact number400-811-8878Thank you for your support!