Products

- Description

- Specifications

- Video

-

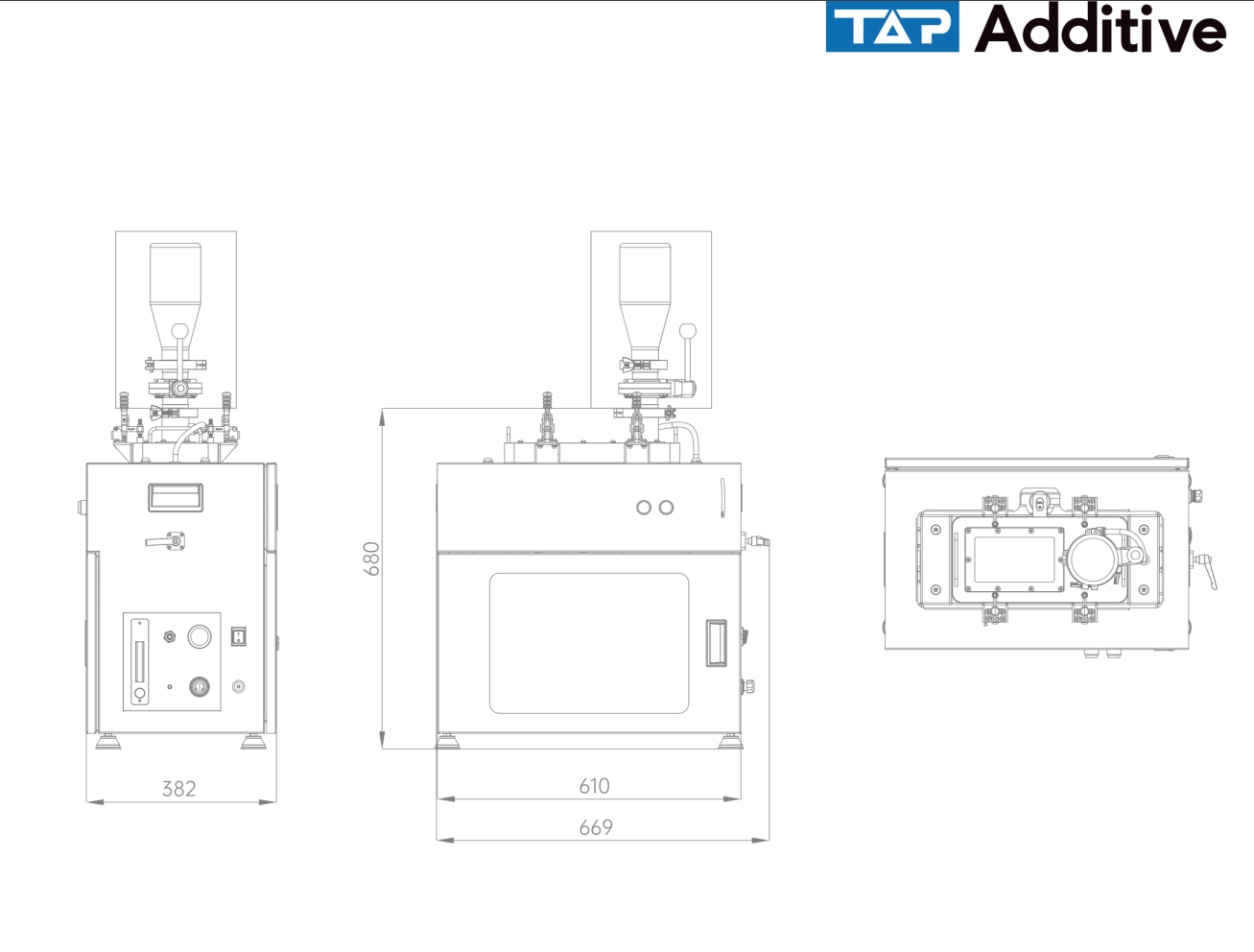

- Commodity name: Sieving station

- Commodity ID: TSF-F10 VAD

Product description

The TSF-F10 series features a compact footprint, integrating powder recycling and sieving functionalities, primarily engineered for laboratory, medical, and dental environments requiring precision processing of small-volume metallic powders. Equipped with an imported ultrasonic mesh-cleaning system, the unit achieves up to 10-fold efficiency enhancement in sieving operations. Through its ultrasonic wave transmission mechanism, the system delivers acoustic energy directly to sieving meshes, facilitating rapid metallic powder throughput while preventing particle adhesion. This technological configuration effectively reduces mesh clogging risks, minimizes mechanical load on sieving components, ensures persistent mesh porosity integrity, and consequently enables high-efficiency fine-powder classification with concurrent 23-40% extension of mesh service life.

The system specifically addresses oxidation-prone and explosive fine metal powders (e.g., aluminum, titanium) exhibiting heightened oxidation sensitivity and explosion risks when exposed to ambient air. Our integrated inert gas system synergizes with automated real-time oxygen concentration monitoring throughout operational phases, achieving 99.97%±0.02% purity retention in post-processed powders while ensuring stable hazardous material handling. Third-party certified explosion-proof compliance (ATEX/IECEx equivalency standards) guarantees operational safety protocol adherence.The product architecture incorporates ergonomic design principles through space-optimized dimensions and workflow-aligned interfaces, demonstrating 38% reduction in repetitive motion strain compared to conventional systems. This human-centered engineering approach minimizes operator fatigue while enhancing operational satisfaction indices by 27% (ISO 9241-210 validated).

Product Features - Explosion-proof design, CE certificate, ATEX certificate.

- Over-sized powder collection, continous and efficient screening.

- Europe imported ultrasonic system with high efficiency.

- Inert gas protection, provide higher powder quality.

- Ease of changing sieving mesh.

- Mesh frame is produced by CNC, with good sealing ability.

- Lever sensor.

-

Technical data Order NO. TSF-F10 VA TSF-F10 VAD Ex Mark Ex h IIIC T100°C Da* Ex h IIIC T100°C Da* Internal: II 1D T130°C; External: safety area Ambient Temperature -20°C..... + 40°C +5°C..... + 40°C

Rated Voltage (V) 220/230 Rated Frequency (Hz) 50/60 Rated Power (W) 100 Oxygen monitoring No Yes

Inert gas pressure(bar) 1-2 Ultrasonic Power (W)(Max) 100 Mesh diameter 322×141 Mesh size( μm) 25-250 Filter grade H Sound level (dB) ≤60 Remark:This products used in safe area, the house inside are classified as a explosive environment.Outline size L*W*H(mm):669*382*1010

Previous Page

Next Page

Previous Page

Next Page

For further information, please call the contact number400-811-8878Thank you for your support!

For further information, please call the contact number400-811-8878Thank you for your support!