Products

THV-200/400 SERIES

HIGH VACUUM DUST COLLECTOR

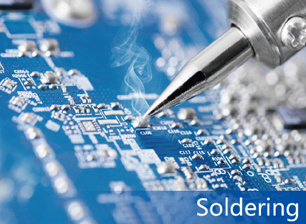

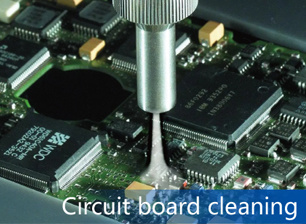

As an industrial grade dust removal equipment,High vacuum dust collector is specially used to collect and purify dry smoke and dust without oil. It is widely used in welding,cutting, grinding and other mechanical processing as well as pharmaceutical industry, local cleaninand other industrial environments.

- Description

- Specifications

- Video

-

- Commodity name: HIGH VACUUM DUST COLLECTOR

- Commodity ID: THV-200/400 SERIES

As an industrial grade dust removal equipment,High vacuum dust collector is specially used to collect and purify dry smoke and dust without oil. It is widely used in welding,cutting, grinding and other mechanical processing as well as pharmaceutical industry, local cleaninand other industrial environments.

INTRODUCTION · Side Channel Vortex Blower

The side channel vortex blower enables the dust collector to generate a negative pressure exceeding -20 kPa. Combined with accessories such as small-diameter piping systems and suction hoses, it directly captures smoke and dust at the source. The airflow capacity varies by model, suitable for single-point capture or dual-workstation applications.

· High Negative Pressure Sedimentation Filtration

Under high negative pressure, welding fumes and dust enter the chamber through the suction hose. A cylindrical filtration chamber creates rotating airflow—large particles (e.g., dust or welding slag) settle along the chamber wall into the dust bin due to centrifugal force, while fine particles follow the airflow into the filter cartridge zone. Tiny dust particles remain on the cartridge surface, and clean air flows through the cartridge into the blower before being discharged indoors.

· Compressed Air Automatic Dust Cleaning System

Equipped with a compressed air automatic dust cleaning system, the dust collector uses rationally partitioned filtration chambers to achieve zoned online cleaning. It supports time-based automatic cleaning control for efficient maintenance.

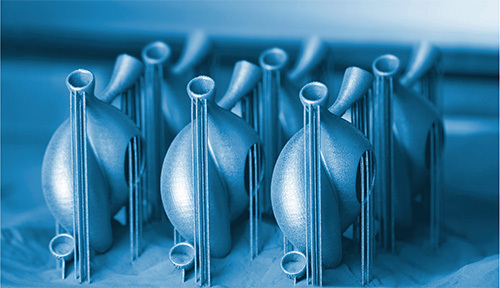

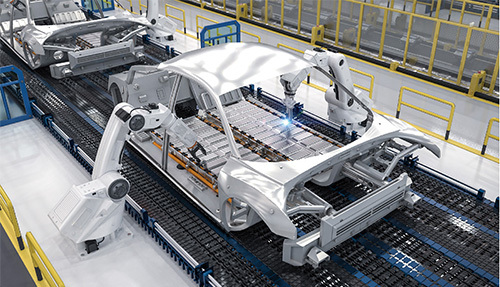

APPLICABLE FIELDS

AEROSPACENEW ENERGY

AEROSPACENEW ENERGYFOOD &

PHARMACEUTICALNEW MATERIALELECTRONICSWORKING PRINCIPLE ■ The dusty air flow enters the cylindrical filter chamber at high speed along the tangent direction, the large dust or welding slag settles into the barrel along the wall of the cylinder,The fine dust will be intercepted by the high efficiency filter when the airflow passes through the surface of the filter cartridge.Clean air flows into the blower from the inner wall of the filter cartridge and is discharged into the room, Emissions to the outside of the machine.

■ Dust collector is equipped with compressed air pulsating dust-cleaning system,It can switch between differential pressure control automatic dust cleaning and Timing control automatic dust cleaning at any time,keep the good working condition of the

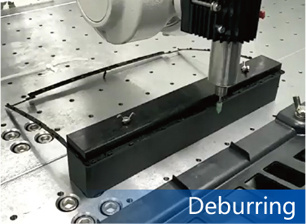

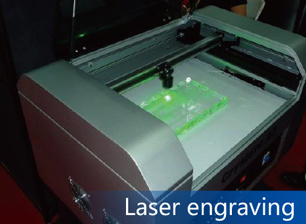

filter cartridge.APPLICATION PROCESS

-

TECHNICAL DATA TYPE THV-200 TTV-400 Protection degreeIP55 Rated power(kW)2.2 5.5 Rated voltage(V)380 380 Rated frequency(Hz)50 50 Max airflow(m³/h)320 520 Max pressure(KPa)-26 -30 Working data(m³/h@KPa)220@-22 400@-21 Capacity(L)60 Cartridge quantity(psc)1 Filtration area(m²)7 Blower typeSide channel high pressure blowerFilter degreeH13 Dust cleaningCompressed air pules cleaningSuction inlet size(mm)50 70 Sound level(dB)≤74 -

Previous Page

Next Page

Previous Page

Next Page

For further information, please call the contact number400-811-8878Thank you for your support!

For further information, please call the contact number400-811-8878Thank you for your support!