Products

THW series

Explosion-proof high vacuum wet type dust collector

Innovative Wet Filtration Method: Primarily designed to handle flammable, explosive, viscous/sticky, fibrous dust, and smoke containing sparks or high temperatures generated during industrial processes.

- Description

- Specifications

- Video

-

- Commodity name: Explosion-proof high vacuum wet type dust collector

- Commodity ID: THW series

Innovative Wet Filtration Method: Primarily designed to handle flammable, explosive, viscous/sticky, fibrous dust, and smoke containing sparks or high temperatures generated during industrial processes.

INTRODUCTION ■ Intrinsically Safe Explosion/Fire Prevention Design

Employs liquid inertization technology for explosion and fire prevention.

■ High-Performance Blower

Standard with side-channel high-negative-pressure blower (explosion-proof blower optional), featuring stable performance, low noise, and 24/7 continuous operation.

■ Wet Filtration Method

Ideal for handling high-temperature, highly reactive, and flammable dust, offering high safety and low maintenance costs.

■ High-Efficiency Dust Collection

Combines advantages of impingement-type and cyclonic-type dust collection, effectively removing fine dust and atomized particles.

■ HEPA High-Efficiency Filter Cartridge

Equipped with two-stage HEPA high-efficiency filter cartridges, achieving ≥99.9% filtration efficiency for 0.3μm particles.

■ Whole-Unit Explosion-Proof (Explosion-Proof Type)

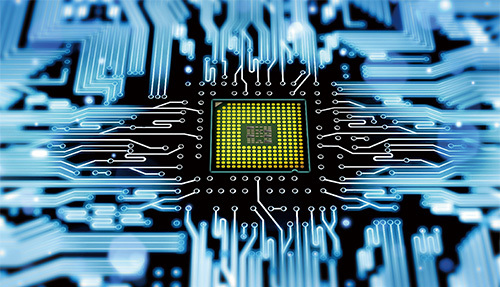

Certified by national authorities for whole-unit explosion-proof compliance, ensuring operational safety.APPLICATION

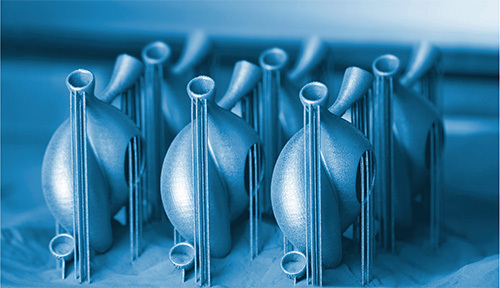

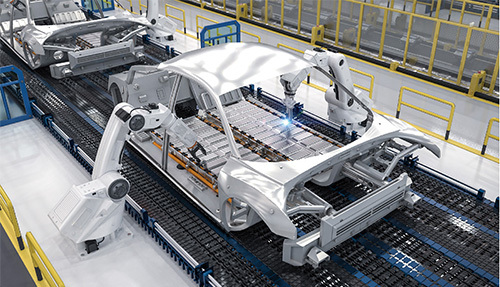

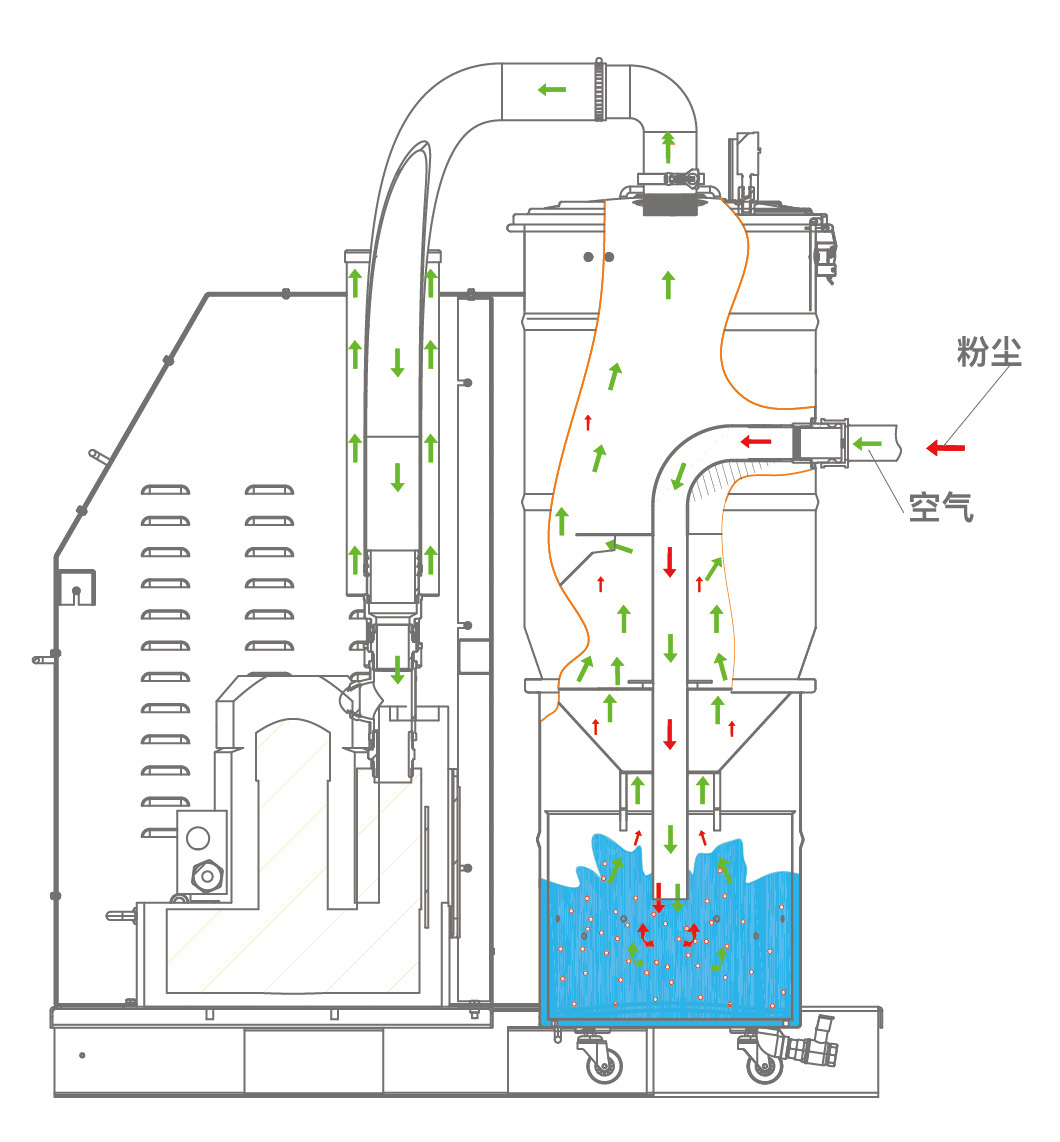

Aerospace New energy Chemical Mechanical Electronic WORKING PRINCIPLE Spark and Flammable Dust Handling: Sparks and flammable dust enter the dust collector with the airflow. High-speed airflow impacts the liquid surface, atomizing the liquid and mixing it with gas. This encapsulates particles in the airflow, quenches high-temperature particles, and isolates them from air to prevent combustion and explosions.

Liquid Droplet Separation: Droplets are forced toward the collector’s inner walls by centrifugal force under swirling airflow, converging along the walls to separate from gas. The droplets then flow back to the liquid storage tank at the collector base for sedimentation.

Post-Filtration Gas Treatment: Filtered gas undergoes secondary purification via HEPA filter cartridges to achieve ultra-low emission concentrations.

APPLICATION PROCESS

-

TECHNICAL DATA TYPE THW-300EX THW-400EX THW-600EX Ex markEx tb IIIC T130°C Dc Rated power(kW)4 5.5 7.5 Rated voltage(V)380 Rated frequency(Hz)50 Max airflow(m³/h)320 520 730 Max pressure(KPa)-26 -30 -27 Primary filterWet type, HEPAPort size(mm)φ38/40 Capacity(L)50 Max dust collection capacity(L)9 Noise(dB)73 75 78

Previous Page

Next Page

Previous Page

Next Page

For further information, please call the contact number400-811-8878Thank you for your support!

For further information, please call the contact number400-811-8878Thank you for your support!